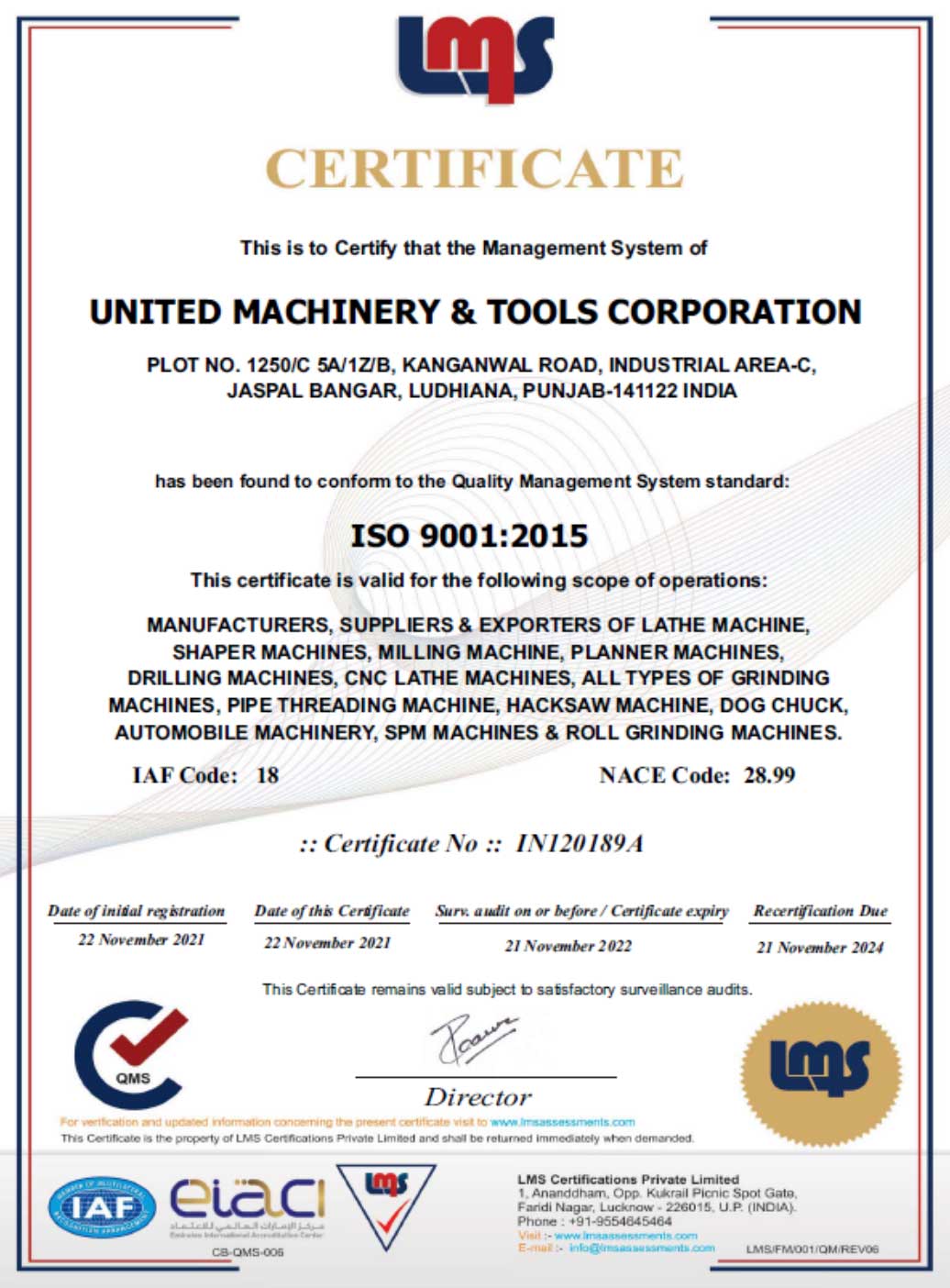

Quality Certification

United Machinery & Tools Corporation

United Machinery & Tools Corporation are known for producing only the best quality and highly reliable products such as all kinds of Heavy Duty Lathe Machines, Shaper Machines, Milling Machines, Drill Machines etc. The long service life of United Machinery & Tools Corp are the result of best quality management in development, production, distribution and service. Our ambitious & talented development engineers are constantly striving to improve existing solutions in terms of precision, ease of application and economic efficiency. No wonder we are counted as best when it comes to product innovation.

Company's Quality Policy

The Company in order to attain excellence, follows its quality policy to the core. We at United Machinery & Tools Corp commit ourselves to put in our best endeavor to achieve total customer satisfaction by applying the following quality policy :-

- Use of Genuine Material

- Producing Quality Goods

- Adhering to delivery schedules

- Continuously upgrading our products

- through up gradation in technology

- Customer Satisfaction

- Competitive Prices

Quality Control

To keep check on quality of products, United has Quality Assurance department. The department keeps a close watch, right from the procurement of raw material to the distribution. To further strengthen the control on equipments, Strenuous efforts are being made from quality control at every stage of manufacturing. This system ensures strict adherence to specification from the raw material stage, wherein we check chemical as well physical properties of it. All raw material accepted and passed are free from cracks and surface discontinuities.

The Quality Control Process

All our Products are checked with Ring & Plug Gauges, Micrometer, Vernier Calipers & Slip Gauges are periodically checked and calibrated & get them checked by approved agencies as well.

Our Quality Management System based on the International Standard Specification. The system ensures that our products adequately comply with the standards and specifications required by the customers. Our QA/ QC activities guarantee that the material supplied by us comply with the required standard specifications. They also ensure that all the employees affecting and well-equipped to perform their assigned tasks with proficiency and perfection.

The inspection activity starts right from the receipt of Raw Material and continues throughout the manufacturing process until final shipment. Trained and highly qualified QC staff conducts inspections at every stage.

For any Query, Contact Our Team