Drill Machines

United Machinery & Tools Corporation

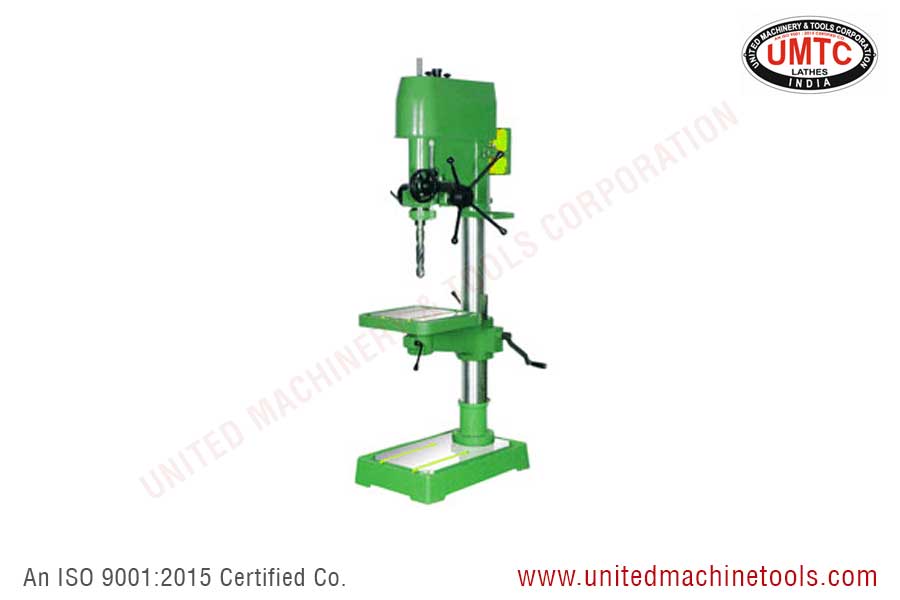

Drilling Machine / Pillar Type Drill Machine

| Specification | Pillar Drill Machine |

| Tilting working table |

FIXED |

| Drilling capacity | 40 mm |

| Pillar Diameter | 121 mm |

| Spindle nose to table distance | 595 mm |

| Distance from spindle nose to base distance | 1050 mm |

| Distance from spindle center to pillar surface | 320 mm ( MAX ) |

| Table Travel | 480 mm |

| Taper in spindle | MT - 4 |

| Number of speed | 8 Speed |

| Range of Speed (RPM) | 70 to 2000 |

| Table Size (in mm) | 410 x 410 |

| Base size (Machined Area mm) | 440 x 715 |

| Overall Base Size (in mm) | 445 x 720 |

| Spindle Travel | 250 mm |

| Pillar Length | 1450 mm |

| Overall height with pulley guard | 1860 mm |

| V-Belt section | B - 59" |

| Weight (Approx.) | 325 kg. |

| Motor1440 RPM 3 Phase440 volts | 1 HP |

| Shipping Wooden Case Inner Size LxWxH (in mm) |

860x460x1880 mm |

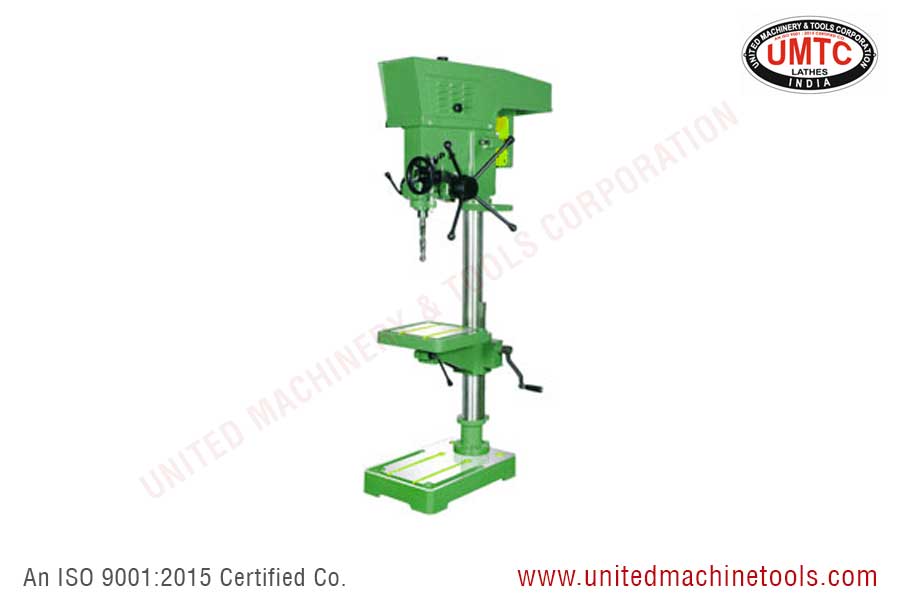

Drilling Machine / Pillar Type Drill Machine

| Specification | Pillar Drill Machine |

| Tilting working table |

FIXED |

| Drilling capacity | 40 mm |

| Pillar Diameter | 121 mm |

| Spindle nose to table distance | 595 mm |

| Distance from spindle nose to base distance | 1050 mm |

| Distance from spindle center to pillar surface | 320 mm ( MAX ) |

| Table Travel | 480 mm |

| Taper in spindle | MT - 4 |

| Number of speed | 8 Speed |

| Range of Speed (RPM) | 70 to 2000 |

| Table Size (in mm) | 410 x 410 |

| Base size (Machined Area mm) | 440 x 715 |

| Overall Base Size (in mm) | 445 x 720 |

| Spindle Travel | 250 mm |

| Pillar Length | 1450 mm |

| Overall height with pulley guard | 1860 mm |

| V-Belt section | B - 59" |

| Weight (Approx.) | 325 kg. |

| Motor1440 RPM 3 Phase440 volts | 1 HP |

| Shipping Wooden Case Inner Size LxWxH (in mm) |

860x460x1880 mm |

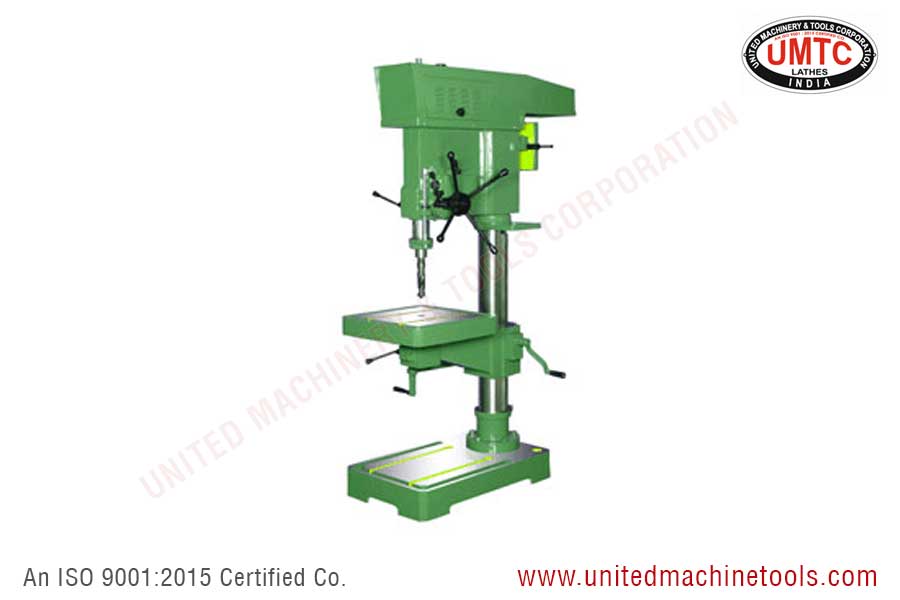

Drilling Machine / Pillar Drill Machine (Extra Heavy)

| Specification | Pillar Drill Machine |

| Tilting working table |

FIXED |

| Drilling capacity | 40 mm |

| Pillar Diameter | 135 mm |

| Spindle nose to table distance | 495 mm |

| Distance from spindle nose to base distance | 1000 mm |

| Auto feed speed |

(applies to PSL-40A only) 0.04 or 0.08 |

| Distance from spindle center to pillar surface | 380 mm ( MAX ) |

| Table Travel | 500 mm |

| Taper in spindle | MT - 4 |

| Number of speed | 8 Speed |

| Range of Speed (RPM) | 60 to 2000 |

| Table Size (in mm) | 490 x 490 |

| Base size (Machined Area mm) | 820 x 490 |

| Overall Base Size (in mm) | 825 x 495 |

| Spindle Travel | 250 mm |

| Pillar Length | 1475 mm |

| Overall height with pulley guard | 1840 mm |

| V-Belt section | B - 74" |

| Weight (Approx.) | 500 kg. |

| Motor1440 RPM 3 Phase440 volts | 2 HP |

| Shipping Wooden Case Inner

Size LxWxH (in mm) |

1200x540x1880 mm |

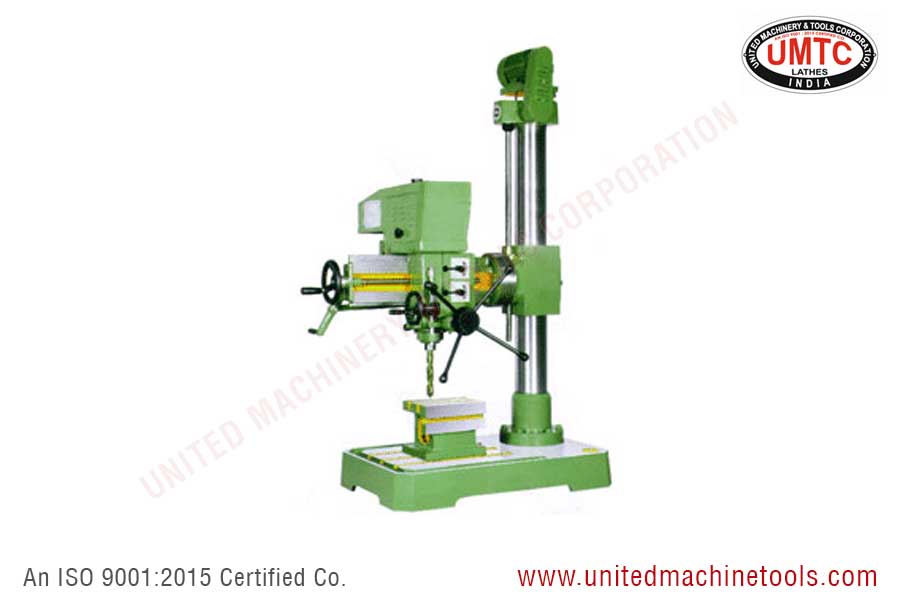

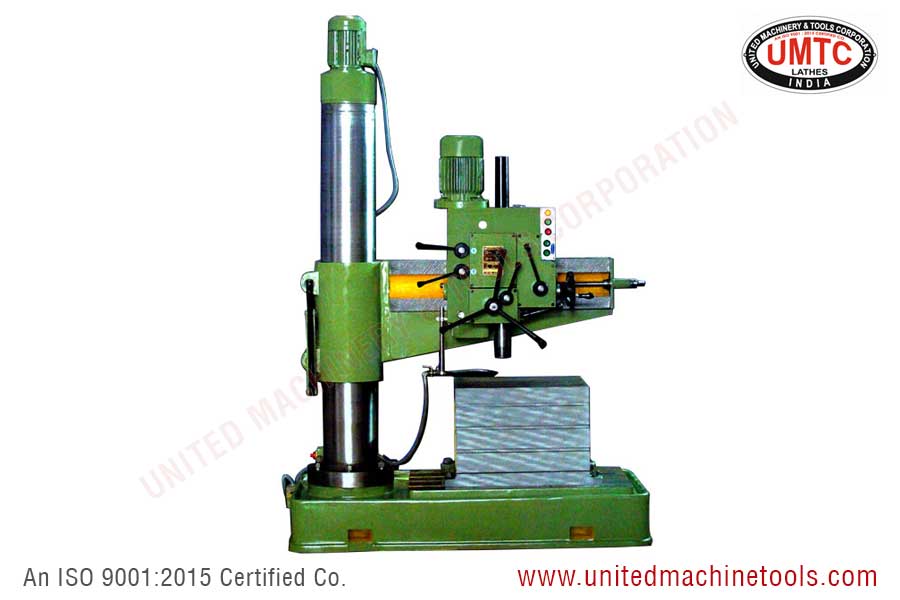

Drilling Machine / Radial Drill Machine

| Specification |

Radial Drill Machine |

| Drilling capacity |

25 mm |

| Pillar diameter | 130 mm |

| Spindle nose to table distance | 675 mm |

| Distance from spindle nose to base distance | 875 mm |

| Distance from spindle center to pillar surface | 635 mm ( MAX ) |

| Taper in spindle | MT - 3 |

| Number of speed | 8 Speed |

| Range of Speed (RPM) | 130 to 2600 |

| Work Table Size (in mm) | 200 x 200 x 250 |

| Base size (Machined Area mm) | 585 x 915 mm |

| Overall Base Size (in mm) | 610 x 940 mm |

| Spindle Travel | 185 mm |

| Pillar Length | 1265 mm |

| Overall height with pulley guard | 1700 mm |

| V-Belt section | B - 43" & A - 23" |

| Weight (Approx.) | 475 Kgs. |

| Motor1440 RPM 3 Phase440 volts | 1 HP & 0.5 HP |

| Shipping Wooden Case Inner

Size LxWxH (in mm) |

1030 x 770 x 1770 |

Heavy Duty Radial Drilling Machine

| Technical Specifications Chart | ||

| Model | S-32 | S-50 |

| Drilling Capacity in steel | 32mm | 50mm |

| Min. & Max. Drilling Radius from column | 300mm - 100mm | 300mm - 1150mm |

| No. of speeds | 8 / 80-890 RPM | 4 / 88-415 RPM |

| Feeds / Range | 2 / 0.1 & 0.2 mm / rev. | 3 / 0.10-0.30-0.20 mm / rev. |

| Quill | 150mm | 175 mm |

| Morse taper in spindle | No.3 | No. 4 |

| Distance between spindle nose and table | 500mm | 825 mm |

| Size of work table | (400 x 550 x 400 ) mm | (455 x 610 x 455) mm |

| Motor for Drilling head | 2 H.P. | 3 H.P. |

| Motor for arm elevating | 1 H.P. | 2 H.P. |

| App. Weight of machine | 1 1/2 Tons | 2 Tons |

| Overall Height of machine | 2050 mm | 2450mm |

Salient Features:

1. The bearing system of the work spindle is capable of taking axial as well as Radial work loads of the machine to perform vertical boring jobs besides drilling.

2. The main gear box is well covered from dust and iron chips.

3. All gears in Drilling Head are pump lubricated and gears in elevating gear box are bath lubricated.

4. All gears are made from special alloy steel, heat-treated property and lapped.

5. All shafts are made from carbon alloy steel and runs on Ball Bearings which are easily available from any market for replacement.

6. The main Electric motor is coupled to main gear box by a shock absorbing coupling.

7. The Horizontal movement of the Drilling head is made by a screw so that it can be used as a keyway milling.

Note : In accordance with our continues improvements we reserve the right to change the design and specifications without any notice.

For any Query, Contact Our Team