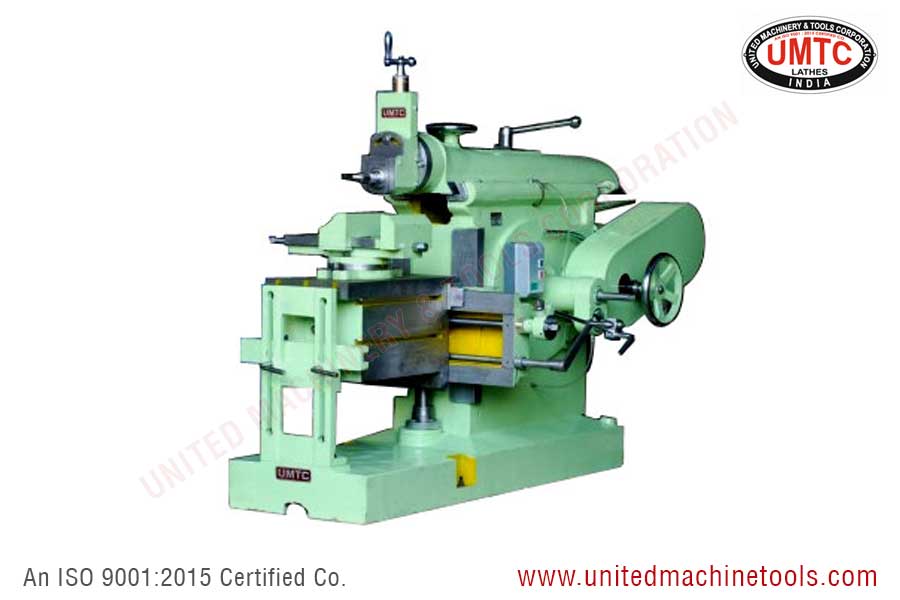

Shaper Machines

United Machinery & Tools Corporation

Shaper Machine Cone Pulley Drive & All Geared Shaping Machines

|

SHAPING MACHINE SPECIFICATION TABLE |

||||||||

|

CAPACITY |

12" | 18" | 24" | 30" | ||||

| Inches | mm | Inches | mm | Inches | mm | Inches | mm | |

|

Length of Ram Stroke |

12 | 305 | 18 | 457 | 24 | 610 | 30 | 762 |

|

Length of Ram |

26 | 660 | 40 1/2 | 1029 | 50 | 1270 | 55 | 1699 |

|

Length of Width of Ram Bearing |

26x7 | 660x178 | 28 1/2x9 | 724x229 | 33x11 1/2 | 838x292 | 39x12 46/8 | 975x323 |

|

Max & Minimum distance from table to Ram |

10x1 | 257x25 | 15x1 | 406x25 | 18x3 | 457x89 | 19x3 | 483x76 |

|

TABLE |

||||||||

|

Working surface of table |

12x8 | 305x228 | 18x11 1/2 | 457x292 | 24x14 | 610x356 | 30x15 | 711x406 |

|

Max Table Travel Horizontal |

16 1/2 | 419 | 18 | 457 | 24 | 610 | 30 | 750 |

|

Max Table Travel Vertical |

9 | 229 | 13 | 350 | 15 | 381 | 16 | 406 |

|

Angular Movement of Table on either sides |

60°L 60°R | 60°L 60°R | 60°L 60°R | 60°L 60°R | ||||

|

TOOL HEAD |

||||||||

|

Max. Vertical Travel of Tool Slide |

5 | 140 | 6 | 152 | 6 | 152 | 8 | 200 |

|

Maximum Swivel of Tool Head |

60°L 60°R | 60°L 60°R | 60°L 60°R | 60°L 60°R | ||||

|

LENGTH OF MAIN SLIDE BASE |

23" | 29" | 36" | 41" | ||||

|

Length of Width of base |

37x18 | 940x457 | 50x17 1/4 | 1270x433 | 64x23 | 1600x585 | 72x26 | 1800x650 |

|

SPEED & FEEDS |

||||||||

|

Cone Pulley Belt |

3 | |||||||

|

Dia of Clutch Pulley |

9 1/4 | 235 | 12" | 3 305 | 12" | 4 305 | 14" | |

|

Range of Ram speeds |

4 | 355 | ||||||

|

Stroke per minute |

3 | 4 | 4 | 8,16,32,48 | ||||

|

Dia of Motor Pulley |

2 1/2 30,60,90 60 | 2 3/4 16,32,64,96 70 | 2 3/4 12,24,48,72, 70 | 2 3/4 | 76 | |||

|

Range of Table Feed per stroke of Ram |

0.009 | 0.229 | 0.009 | 0.229 | 0.009 | 0.229 | 0.009 | 0.229 |

|

Range of Tool Head feed |

||||||||

|

DRIVE & ELECTRICAL EQUIPMENTS |

Hand Feed | Hand Feed | Hand Feed | Hand Feed | ||||

|

Electric Motor |

1.5H.P. | 1.5H.P. | 1.5H.P. | 1.5H.P. | ||||

|

Drive Motor |

1440RPM | 1440RPM | 1440RPM | 1440RPM | ||||

|

Main Switch Starter ( Push Button Type ) |

3.5AMP | 3.5AMP | 5AMP | 5AMP | ||||

|

SPECIFICATION OF VICE |

||||||||

|

Overall Dimensions |

5" | 8" | 12" | 13 1/4 | ||||

|

Length |

48 | 1219 | 62 | 1580 | 78 | 1981 | 86 | 2150 |

|

Width |

30 | 762 | 37 | 940 | 43 | 1092 | 48 | 1219 |

|

Height |

54 | 1371 | 55 | 1400 | 63 | 1600 | 62 | 1550 |

|

|

||||||||

A shaper machine is a type of machine tool that uses a linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. It cuts, shapes, and profiles various materials, producing flat and angular surfaces. Here are some key aspects of a shaper machine:

Components of a Shaper Machine:

Bed: The bed is a heavy, rigid casting on which all the other components are mounted. It provides support to the column and the worktable.

Column: The column is a vertical cast that houses the ram and provides support for it.

Ram: The ram holds the tool head and reciprocates in the vertical plane. The cutting tool is mounted on the ram.

Tool Head: The tool head holds and supports the cutting tool. It can swivel and feed in and out to perform different operations.

Saddle: The saddle is mounted on the top of the bed and can move transversely. It supports the cross-slide, which in turn holds the tool head.

Cross-Slide: The cross-slide can move longitudinally on the saddle. It supports the tool head and can be clamped at any desired position.

Worktable: The worktable is mounted on the saddle and can swivel about a horizontal axis. The workpiece is mounted on the worktable.

Clapper Box: The clapper box is attached to the tool head and allows the tool to lift clear of the work during the return stroke, reducing wear on the tool and the workpiece.

Shaper machines play a significant role in manufacturing processes by shaping and finishing workpieces with precision and efficiency.

For any Query, Contact Our Team