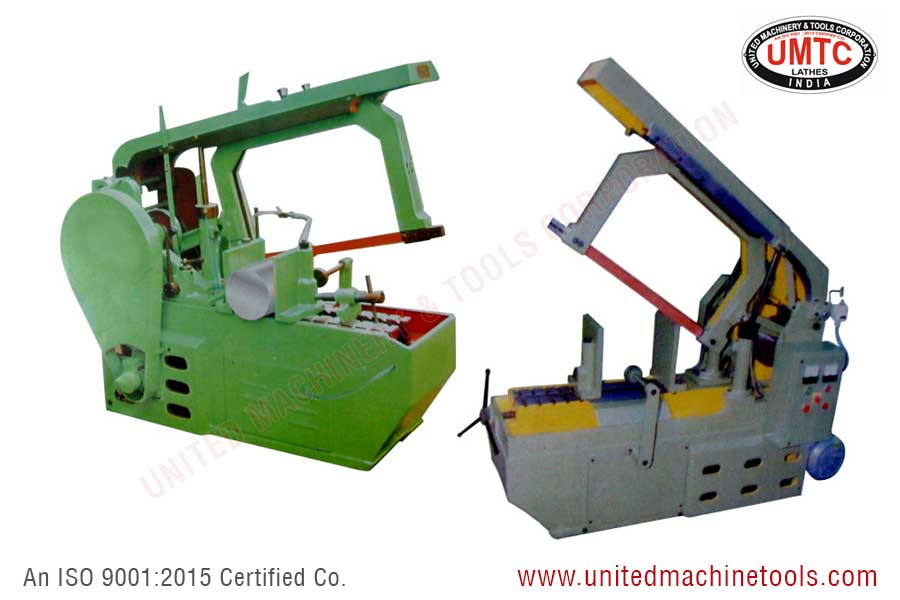

Hacksaw Machines

United Machinery & Tools Corporation

Extra Heavy Duty Roll Turning Lathe Machines

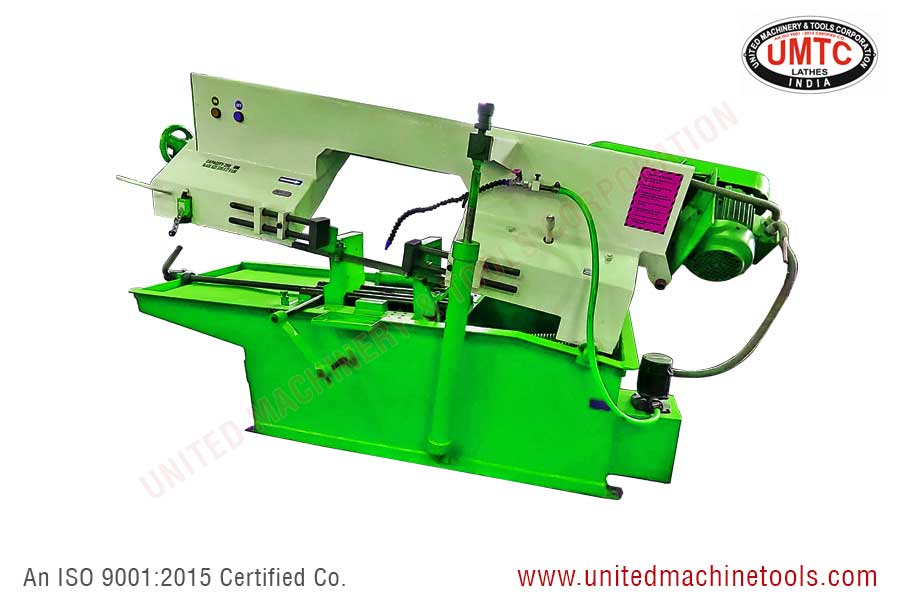

Bandsaw Machine

| TECHNICAL SPECIFICATION - Hacksaw Machine | ||||||||||

| Size | 7" | 8" | 10" | 12" | 14" | 16" | 18' | 20" | 24" | 7" |

| Model | H.H. 175 | H.H. 200 | H.H. 250 | H.H. 300 | H.H. 350 | H.H. 400 | H.H. 450 | H.H. 500 | H.H. 600 | M.H. 175 |

| Capacity of Round Bar | 7" 175mm |

8" 200mm |

10" 250mm |

12" 300mm |

14" 350mm |

16" 400mm |

18" 450mm |

20" 500mm |

24" 600mm |

7" 175mm |

| Capacity of Square Bar | 5" 125mm |

6" 150mm |

8" 200mm |

10" 250mm |

11" 275mm |

13" 325mm |

14" 350mm |

15" 375mm |

18" 450mm |

5" 125mm |

| Blade Size | 14" | 14"to16" | 16"to18" | 18"to20" | 20"to22" | 22"to24" | 26"to28" | 28"to30" | 30"to36" | 14" |

| Stroke | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" | 5 1/2" |

| No. of Stroke / Minute | 100to120 | 100to120 | 85to100 | 85to100 | 80to90 | 70to80 | 60to85 | 60to85 | 60to85 | 80to100 |

| Electric Motor | 1 H.P. | 1 H.P. | 1.5 H.P. | 2 H.P. | 3 H.P. | 3 H.P. | 5 H.P. | 5 H.P. | 7.5 H.P. | 1 H.P. |

| R.P.M. | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 960 | 960 | 960 | 1440 |

| Length | 39" | 40" | 44" | 47" | 51" | 54" | 58" | 62" | 64" | 37" |

| Breadth | 22" | 22" | 25" | 25" | 26" | 28" | 29" | 30" | 30" | 18" |

| Height | 27" | 28" | 32" | 36" | 40" | 46" | 50" | 54" | 57" | 25" |

| Weight in Kgm ( Approx ) | 350kg | 375kg | 450kg | 500kg | 650kg | 700kg | 1000kg | 1100kg | 1200kg | 150kg |

| Packing Size in Inches | 43x25x31 | 43x25x31 | 48x26x35 | 49x26x37 | 55x27x41 | 59x27x45 | 62x30x56 | 67x32x56 | 70x32x59 | 41x22x29 |

| In accordance with our continuous improvement we reserve the right to change the specifications without any notice. | ||||||||||

SALIENT FEATURES:

1. Automatic, Two Speed.

2. Fast Precision cutting-Accurate True.

SAW FRAME:

The saw frame is of rigid construction and runs in prismatic guide ensuring a square and parallel cut. The cutting of the material takes place on the draw stroke and the blade is hydraulically lifted out of contact with the wrok-piece on the forward stroke to prevent wear on the blade.

FEED:

The blade is hydraulically operated by two levers on the dash-pot on linking to an automatic lift of saw frame on completion of cutting cycle while other regulating the rate of down feed, the dash-pot being designed to lift the blade on non cutting stroke.

BED:

The bed is of large size provided with guide ways for holding the material. The vice is rigid construction with one jaw is fixed, while the other is operated by a screwed shaft and nut.

DRIVE:

Power is supplied by a suitable electric motor through V-belts which are full adjustable for tension all drive mechanism being totally enclosed.

COOLANT TANK:

Coolant tank is totally enclosed in the machine base and a constant speed pump supplies the coolant the point of contact between the blade and work-piece.

SPEED:

Two cutting speed are provided by us, the mechanism allows for the most suitable speed to select for material being cut.

ELECTRICAL EQUIPEMNTS:

A direct-on-line push-button, starter incorporates an adjustable trip mechanism and stops the machine as the blade is cleared off the workpiece.

Note: In accordance with our continues improvements we reserve the right to change the design and specifications without any notice.

For any Query, Contact Our Team